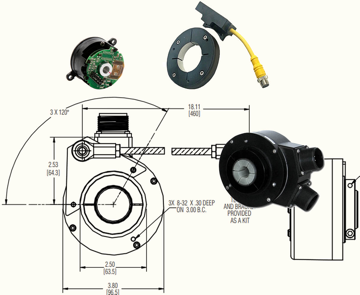

In this example the fault output from an HS35IQ encoder was connected to a Rockwell PLC. A simple single line of ladder logic was used to read the fault line from the encoder and turn on an LED when a fault is present. The LED is just an easy way to indicate the fault was successfully read from the encoder but other solutions such as alerting maintenance are possible by utilizing the fault output function.

-

{{#each queries.results}}

- {{query}} {{/each}}

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

{{/if}} {{#if attributes.installation_manual_link}} Download Installation Manual {{/if}}

{{#if attributes.list_price}} {{#if attributes.leadtime}} Buy Now!

{{/if}} {{/if}} View Product Info

{{/if}} {{#if attributes.installation_manual_link}} Download Installation Manual {{/if}}

{{#if attributes.family_page_link}} View Series Info {{else}} More Info {{/if}}

{{/if}} {{#if attributes.installation_manual_link}} Download Installation Manual {{/if}}

More Info

{{/if}} {{#if attributes.installation_manual_link}} Download Installation Manual {{/if}}

More Info

Other Categories

Optical Rotary Encoders

Magnetic Rotary Encoders

Hollow-Shaft Encoders

Hub-Shaft Encoders

Shaft Encoders

Miniature Encoders

Hazardous Area Encoders

Non Contact Encoders

Bearingless Encoders

Ethernet Protocol Encoders

Service & Support Overview

Product Quicklinks

Competitor Parts List

Discontinued Encoder Guide

Literature Library

RMA Request

Technical Support

Product Manuals & Installation Guides

Knowledge Center

Technology

How to Choose Feedback

Application Examples

Case Studies

Encoder Issues and Troubleshooting

White Paper Downloads

Literature Library

Power Point Downloads

Videos

Featured Links

Motor Encoders

Quadrature Encoders

Optical Encoders

Magnetic Encoders

How to Specify a Resolver

Draw Wire Encoders

Hall Effect Encoders

Encoder Accuracy vs Resolution