Magnetic Encoders

The heart of an encoder is the way that it provides information – that’s the encoder engine. An encoder engine takes the positional and speed information and then supplies the signal that is sent to the application.

The engine type is categorized by the method that the control information is determined. There are two major categories:

- Optical encoder engines, both masked and phased array

- Magnetic encoder engine

The differences in the way that a magnetic encoder and an optical encoder gather information lead to performance differences in different operating environments. Understanding how an optical and magnetic encoder work can help determine what kind of encoder is best suited to your application. See all magnetic encoder models here.

What are magnetic encoders?

Magnetic encoders are a type of rotary encoder that use sensors to identify changes in magnetic fields from a rotating magnetized wheel or ring.

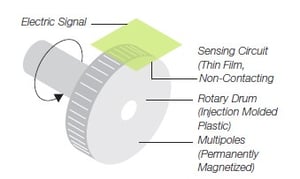

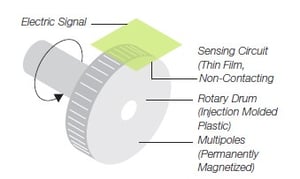

There are 3 major components in a magnetic encoder:

- Sensing Circuit

- A rotating wheel or ring

- A series of magnetic poles around the circumference of the wheel or ring

As the wheel or ring spins past the magnetic sensor, the poles cause a predictable response in the sensor based on the strength of the magnetic field. The magnetic response is fed through a signal conditioning electrical circuit and output as a digital signal to the controlling device.

The number of magnetized pole pairs on the wheel pole, the number of sensors, and the type of electrical circuit all work together to determine the resolution of the magnetic encoder. The key to using magnetism as the element to produce a signal is that it is unaffected by very demanding environments – including dust, moisture, and extreme temperatures, and shock.

How Do Magnetic Rotary Encoders Work?

An optical encoder uses light (optics) to identify unique positions for the encoder. A magnetic encoder uses the same principle to determine a position as an optical encoder, but it does it using magnetic fields rather than light. There are 3 major types of magnetic encoders:

Magnetic Gear Tooth Sensor or Pickup

The simplest form of a magnetic encoder is a variable-reluctance rotary sensor or magnetic pickup, which consists of a magnetic sensor and a ferromagnetic gear with teeth. When the teeth move past the sensor, the changing magnetic field generates a voltage pulse, which can be converted to speed.

While this type of magnetic rotary encoder is simple and affordable, the output resolution is mechanically limited by the number of gear teeth, limiting typical resolution to 120 or 240 pulses per revolution (PPR).

Magneto-Resistive Encoder

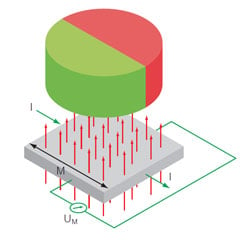

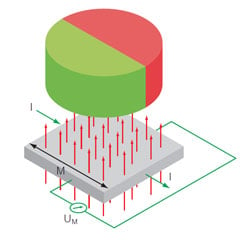

A magneto-resistive sensor consists of an array of patterned thin-film resistors fixed along a wheel or ring with alternative magnetic domains. As the wheel is rotated, the domains pass by the sensor array and the output resistance changes, which produces a sinusoidal signal.

Magneto-resistive encoders can achieve significantly higher resolutions compared to variable-reluctance magnetic encoders. However, magneto-resistive sensors are discrete sensors and are typically larger and difficult to integrate, adding to cost and complexity.

Hall-Effect Magnetic Encoders

A Hall-effect sensor consists of a layer of semiconductor material, connected to a power supply. When a magnetic domain on a wheel or ring passes by a hall-effect sensor, the interaction generates a voltage spike. The amplitude and frequency of the magnetic perturbation can be used to determine speed and displacement.

Hall-effect magnetic encoders integrate both sensor and processor into the same chip and are therefore much more compact than magneto-resistive encoders. They offer higher resolutions and can be manufactured into an array to spread data capture across multiple detectors, averaging out errors and increasing sensitivity.

Learn more about hall effect encoders here

What are magnetic encoders used for?

A magnetic encoder is designed to output reliable digital feedback in the most demanding and harshest of application environments. Unlike optical encoders where the optical code disc can become contaminated by dirt or moisture, magnetic encoders use changes in magnetic fields as the detection method, making them much more reliable in contaminated environments.

Magnetic encoders excel in applications that require broad temperature specifications, high shock and vibration resistance, robust sealing, and contaminant protection while providing output signal reliability and downtime reduction. Popular applications for magnetic encoders include position and velocity feedback in steel, pulp, paper, & lumber mills.

Additional Resources:

Learn more about how to specify a rotary encoder for high temperature and humidity here

See a quick selection guide on how to select hazardous rated encoders

White Paper: Learn How to choose IP rated encoders

White Paper: Magnetic vs. Optical Engines: What You Should Know When Choosing The Right Encoder.

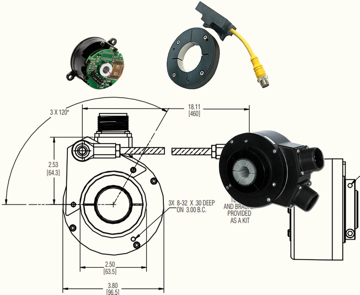

Most Popular Magnetic Encoders