Going for Performance

With a Dynapar

Industrial Encoder

Balancing a tough environment with speed and resolution, providing a versatile and tight-sealed form – an industrial encoder meets the needs when an application requires accuracy coupled with a demanding environment.

An industrial encoder is only one category of rotary encoder; there are a total of four grades, depending on the demands of the operating environment and the precision required by the application. Still, with its balance of durability and performance, an industrial encoder is one of the most common choices for most applications.

A Summary of Different Duties and Different Applications

There are four major categories of encoder which are differentiated by the demands of the operating environment. These run from heavy duty (the most demanding environment) to light duty (the most controlled environment).

Heavy, Servo, and Industrial Encoder Grades

Heavy industrial applications have three classes of encoder:

- Heavy Duty Encoders

- Industrial Duty Encoders

- Servo Motor Encoders

- Light or Commercial Grade Encoders

As the name implies, heavy duty encoders can take the most abuse. They have excellent durability in high temperatures; with particulates, moisture, and contaminants; and under shock or vibration. They have superior speed performance, as well. Heavy duty encoders are the best choice for the most demanding environments – paper, steel, and ore mills where contamination is constant and both shock and heat affect the motor, the stress of aerospace, and the fast factory environments of food and beverage processing. However, heavy duty encoders come at a cost of both size and expense. Unless the environment is truly brutal, a heavy duty encoder may be overkill.

The most common class of encoders is the industrial encoder. An industrial encoder can take punishing operating environments almost as well as heavy duty encoders – rough factories with contamination from dust, particulates, and moisture, in addition to moderate shock and temperature. An industrial encoder offers excellent speed and positioning performance. The class of industrial encoders is versatile.

Servo motor encoders, unlike both heavy duty and industrial encoders, actually reside inside a motor housing. Because it is in a contained environment, it doesn’t have strong sealing, but it has excellent temperature resistance and reliable shock/vibration resistance (which fits its operating environment). Because of its location, servo encoders are smaller and are made for small to mid-sized motors, especially servo and stepper motors. Learn more about servo motor encoders here

Light (or Commercial) Encoder Grade

Light duty encoders are used in more consumer-facing applications like office electronics (copiers, faxes, and computer accessories) and laboratory and medical equipment. These have “people-friendly” environments, meaning conditions are very controlled. Likewise, light duty encoders have good (but not demanding) performance for temperature, shock/vibration, and sealing, with better speed performance and high precision.

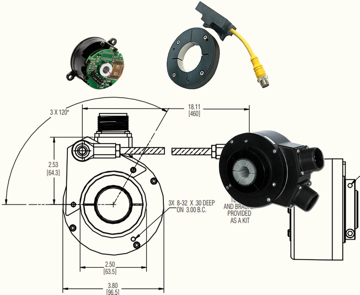

Details on Dynapar’s Industrial Encoder

The industrial encoder selection covers all the typical options:

Additionally, the Dynapar industrial encoder line is engineered with a variety of options so that an industrial encoder can be designed for your specific application and environment:

- Barrierless housings

- Bearing-less movement

- Dual row bearings for ultimate vibration/shock resistance

- Optional shaft seals for even better protection against contaminants

- Unbreakable code disks on some optical versions

With absolute industrial encoders, there are even more options:

- Several different output options

- Multi-turn positioning for applications that require orientation greater than 360° – and all multi-positioning is battery-less because the absolute encoder keeps the orientation even when the unit is powered off

An Industrial Encoder Made to Your Specs

The design of an industrial encoder can be as unique as the application that uses it. And we can help. All Dynapar industrial encoders are made using a philosophy of just-in-time manufacturing. This manufacture-on-demand method means that we make every order to order with adaptable and lean manufacturing methods – no waste in either material or time.

This adaptability also makes it easier for us to do custom industrial encoder orders, not just standard sizes. If you have unique requirements, we can make an industrial encoder to your spec in the quantity you need – quickly.

View all Dynapar rotary encoders.

Dynapar's Most Popular Industrial Encoders