- Industrial Encoder

- Motor Encoders

- Resolvers

- Incremental Encoders

- Absolute Rotary Encoders

- Magnetic Encoders

- Optical Shaft Encoders

- Optical Rotary Encoders

- Hollow-Shaft Encoders

- Quadrature Encoders

- Draw Wire Encoders

- Hall-Effect Encoders

- Hazardous Location Encoders

- Functional Safety Encoders

- Encoder Interface Protocols

- BiSS Encoders

- SSI Encoders

- Gray Code Encoders

- What is an Encoder?

- Electric Motor Controllers

- Types of Safety Encoders

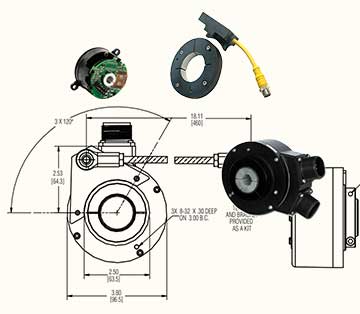

Hall Effect Encoders for OEMs: High-Performance, Reliable Feedback

Precision Magnetic Sensing for Industrial Applications

Dynapar’s Hall effect encoders leverage advanced magnetic phased array technology to deliver high-resolution, robust feedback that OEMs can rely on. Unlike traditional designs, our encoders average signals across multiple detectors, ensuring accuracy even in high-shock, high-vibration environments—ideal for demanding industrial applications.

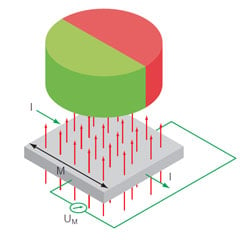

How Hall Effect Encoders Work

Using a magnetic phased array sensor, Hall effect encoders generate precise position and speed feedback by detecting changes in a magnetic field (learn more about magnetic encoder technology). Dynapar’s technology integrates both the sensor and processor into a single IC chip, reducing PCB complexity and increasing reliability while ensuring easy integration into your system.

Why OEMs Choose Dynapar Hall Effect Encoders

- Unmatched durability – Immune to misalignment, shock, and vibration

- Compact, low-maintenance design – No bearings, eliminating a common failure point

- Sealed for harsh environments – Withstands dust, washdowns, and corrosive chemicals

- Reliable digital feedback – Ensures precise control with minimal downtime

Built for Tough Industrial Applications

Dynapar’s Hall effect encoders are trusted across industries where rugged reliability is essential. Whether in construction, agriculture, mining, forestry, or food & beverage, our magnetic encoders provide long-lasting performance in extreme conditions.

Explore our full range of non-contact and heavy-duty Hall effect encoders designed for seamless OEM integration. (learn more about optical encoder technology.)

Hall Effect Encoder Applications

Magnetic hall effect encoders can be extraordinarily robust. Because magnetic encoders are based on an inductive effect, they do not require bearings, which removes a point of failure from the system. Typically, the electronics inside the hall effect encoder are encapsulated so that they are not exposed to the elements. As a result, magnetic hall effect encoders can operate covered in dust in a sawmill or splashed daily in a washdown environment without any additional protection.

A magnetic hall effect encoder is designed to output reliable digital feedback in the most demanding and harshest of application environments. Applications for this technology usually require broad temperature specifications, high shock and vibration resistance, robust sealing, and contaminant protection all while focusing on output signal reliability, easy installation, and downtime reduction. Popular applications for magnetic hall effect encoders include speed and position feedback in construction, agriculture, mining, forestry and in food and beverage applications with wash downs or corrosive chemicals.

See all hall effect non contact encoders

See all heavy duty hall effect magnetic encoders

Looking for a Custom Solution?

Tell us your requirements and our application engineers will help find the right solution today.

Contact Us →