HS35R Hollow-shaft Incremental Optical Encoder

Reliable Hollow-Shaft Encoder Offers Extreme Performance for Heavy Duty Applications

Customize & Buy Now- Up to 5000 PPR

- Optical Sensing

- Up to IP67

Other Categories

Optical Rotary Encoders

Magnetic Rotary Encoders

Hollow-Shaft Encoders

Hub-Shaft Encoders

Shaft Encoders

Miniature Encoders

Hazardous Area Encoders

Non Contact Encoders

Bearingless Encoders

Ethernet Protocol Encoders

Service & Support Overview

Product Quicklinks

Competitor Parts List

Discontinued Encoder Guide

Literature Library

RMA Request

Technical Support

Product Manuals & Installation Guides

Knowledge Center

Technology

How to Choose Feedback

Application Examples

Case Studies

Encoder Issues and Troubleshooting

White Paper Downloads

Literature Library

Power Point Downloads

Videos

Featured Links

Motor Encoders

Quadrature Encoders

Optical Encoders

Magnetic Encoders

How to Specify a Resolver

Draw Wire Encoders

Hall Effect Encoders

Encoder Accuracy vs Resolution

An optical rotary encoder uses a reliable, defined pattern of light-and-dark to determine the position of the shaft and, therefore, the position of an object.

The most basic design for an optical rotary encoder is a mask encoder, but there are a multitude of other options that provide even more stability and more feedback information in an increasing variety of application environments.

An optical encoder is a motion sensing device that utilizes light to convert mechanical motion into electrical pulse signals. It provides accurate position information in industrial applications like robotics, CNC machines, and motor control systems. Accurate motion details, like speed, are achieved sensors that give slightly different signals. They offer high accuracy, resolution, and reliability, and can operate in harsh environments.

The working principle of optical encoders is to use light to detect the position or motion of an object and convert it into an electrical signal. The encoder consists of a light source, a sensor, and a rotating or linear code disk.

As the disk moves, the light source shines through the disk onto the sensor. The sensor detects the pattern of light and dark areas that the sensor and converts into an electrical signal. These offset signals can provide precise motion information, including speed. Some types of encoders utilize multiple signal outputs to create a more stable signal.

Optical encoders create signals that an integrated circuit processes into digital feedback. The number of slots on the disk and precision of the motion sensor determine accuracy and resolution of the encoder.

Reliable Hollow-Shaft Encoder Offers Extreme Performance for Heavy Duty Applications

Customize & Buy Now

1.5" OD Compact Hollow-Shaft Absolute Encoder with Up to 22 Bits ST and 12 Bit MT

Customize & Buy Now

Programmable Hollow Shaft Optical Encoder with Specific Fault Detection Capabilities

Customize & Buy NowAbsolute optical encoders use light to determine the control information. Masked and phased- array are the two types of optical encoders.

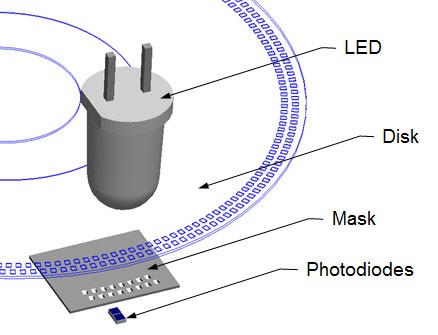

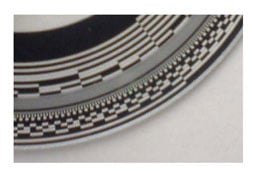

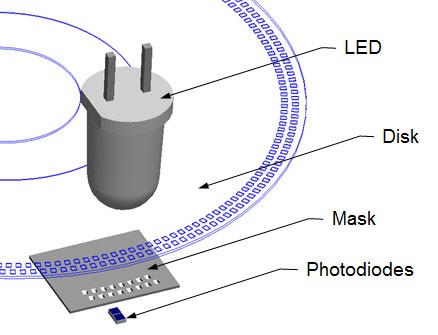

Masked optical encoders have four components: a light source, a sensor, a movable disk, and a fixed mask. The LED light shines through one side of the optical shaft encoder, and the encoder disk has a series of tracks on it.

The mask has a corresponding track for every track on the disk of the optical encoder. The tracks of the mask have many small perforations, called windows. The windows that are open versus closed during rotation determine the position of the optical shaft encoder.

Each arc in the rotation indicates a different position and has a different pattern of open/closed windows. The sensor behind the mask identifies the optical encoders’ current pattern. Each sensor represents one single signal for the optical encoder.

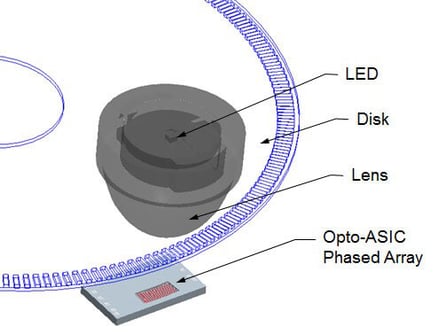

Phased-array optical encoders are even more reliable than masked optical encoders. They use multiple signal outputs to average together to create a single signal that is delivered by the engine. These multiple signals that are used by an optical shaft encoder are called the array.

By using averages instead of a single reading, phased-array optical encoders have much more stable signals. This means they can be used in less stable environments, such as mining or heavy manufacturing, where vibrations or shock could affect a traditional masked optical shaft encoder. They require less precision during installation than traditional masked optical encoders.

Understanding the pros and cons of different encoders can help determine the best encoder for each application. Optical encoders, both masked and phased-array, have many advantages over other types of encoders.

Optical encoders are a type of rotary encoder that uses light to detect position and rotation. They offer several advantages over other types of encoders, such as:

In comparison, magnetic encoders use magnets to detect absolute position, offering better durability and resistance to harsh environments. However, they may not offer the same level of accuracy and resolution as optical encoders.

Overall, the choice between optical and magnetic encoders depends on the specific needs of the application. However, for applications that require high accuracy, reliability, and precision, optical encoders, particularly those using Dynapar optical technology, are an excellent choice.

Optical encoders are versatile devices that find applications in various industries and fields. They are ideal for high-precision, accurate, and reliable applications, offering several advantages over other encoder types.

Optical encoders are also ideal for: medical equipment and devices, printing and packaging machinery, elevators and escalators, automotive and transportation applications, and renewable energy and power generation applications. They are even used in research and development fields, such as robotics, physics, and biology, to provide precise feedback for positioning and movement control.

Absolute optical encoders are widely used in various industries, offering high precision, accuracy, and reliability for applications that require precise feedback for position, speed, and direction control.

Use our selection tool to narrow down your search

© Copyright Dynapar 2025 All Rights Reserved