Our Resolvers - Ultra Performance Feedback

Brushless Resolvers

Housed-Brushless Resolvers Our brushless construction uses a rotary transformer to pass the reference signal to the rotor. This design eliminates the normal brushslop ring sliding contact used in conventional resolvers. Since the brush and slip ring are life limiting components and can be a source of noise in harsh environments, the transformer coupled units enhance reliability and performance.

Industrial Frameless Resolvers Our brushless resolvers are the ideal position feedback transducer for brushless motors, robots and direct drive motors in precision rotary platforms and similar servo applications. They are rugged, reliable, provide absolute position information and are able to operate at 155 degree Celcius and are impervious to most particulate and liquid process contaminants.

Size 11 Brushless Resolvers

Size 11 Brushless Resolvers

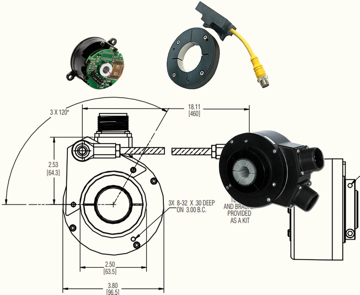

The industry standard Size 11 resolver series has its own precision bearing system, making it ideal for coupling mounting. Its brushless construction uses a rotary transformer to pass the reference signal to the rotor -eliminating components that can limit life and cause noise. Series 11 has excellent angular accuracy and repeatability. Alternatively, the R11 shaft accepts pinions or pulleys for use in rack and pinion or cable measuring systems. Series 11 resolvers are rated up to 155C for high temperature applications. See Series 11 and R11 High Temp Resolver Models

.jpg?width=280&name=R25%20(1).jpg) R25 Heavy Duty Resolver

R25 Heavy Duty Resolver

R25 Heavy Duty resolvers are designed for reliability in adverse operating conditions. Brushless resolvers are the better choice over encoders for applications that involve very high temperature, vibration and shock and dirty environments. Unlike similar duplex-bearing packages, the R25 resolver uses a front-and-rear bearing arrangement that provides two to three times the radial load bearing capacity and up to ten tomes the L10 life of a package with duplex bearings. Rated for ruggedness with IP65 protection, 125C continuous duty, shock resistance to 200g and vibration resistance to 40g.

See Series R25 Heavy Duty Housed Resolver Models

Resolvers for Brushless Motor Feedback

Resolvers for Brushless Motor Feedback

These resolver models provide absolute position feedback for brushless motors, robots and direct-drive motors in precision rotary platforms and similar servo applications. This heavy duty frameless resolver series is ruggedized against vibration and shock, able to operate up to 200 C, resistant to noise, and impervious to most industrial contaminants. Options include multiple speeds, radiation hardened, high temperature, flux shielding technology and stainless steel housings.

Series 10, 15, 21, 31 & 55 Frameless Resolver Models

High Accuracy Frameless Resolvers

High Accuracy Frameless Resolvers

The 700 Series resolver product line provides maximum accuracy and minimum error for demanding position and velocity applications such as robotics. HaroMax resolver sizes 15 and 21 feature a tooth-wound design that reduces electrical error 50 percent less than that of a standard resolver and incorporates windings that are manufactured and installed completely automatically. The automatic installation provides the least amount of part-to-part variation for the greatest consistency. This set of high end resolver models are able to operate up to 200 C with high shock and vibration resistance.

Haromax® 15 & 21 High Accuracy Resolver Models

Need help with your R/D conversion electronics? Take your application requirements to our our friends at Data Device Corporation

Size 11 Brushless Resolvers

Size 11 Brushless Resolvers.jpg?width=280&name=R25%20(1).jpg) R25 Heavy Duty Resolver

R25 Heavy Duty Resolver Resolvers for Brushless Motor Feedback

Resolvers for Brushless Motor Feedback High Accuracy Frameless Resolvers

High Accuracy Frameless Resolvers