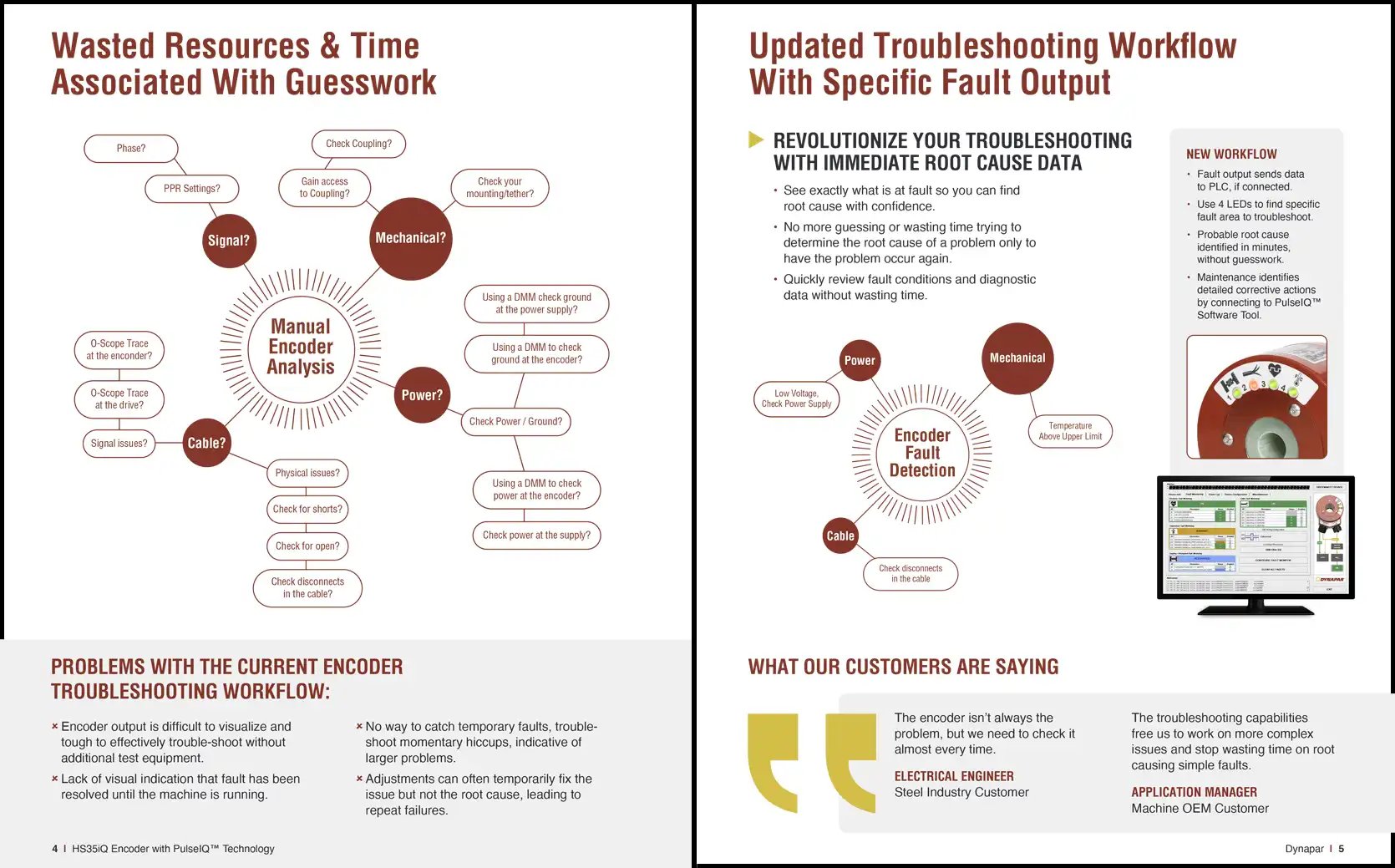

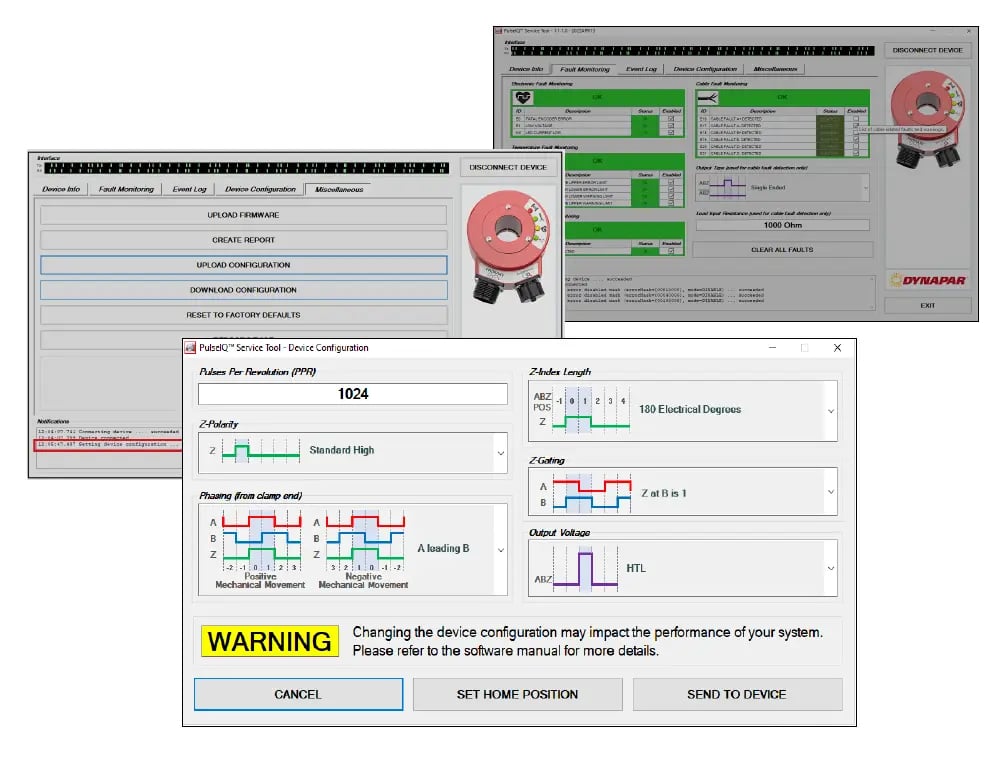

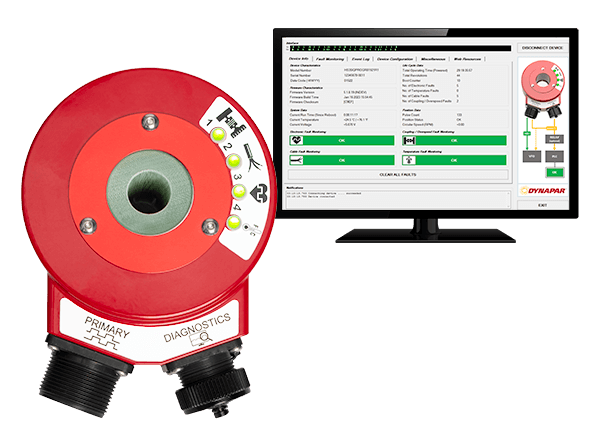

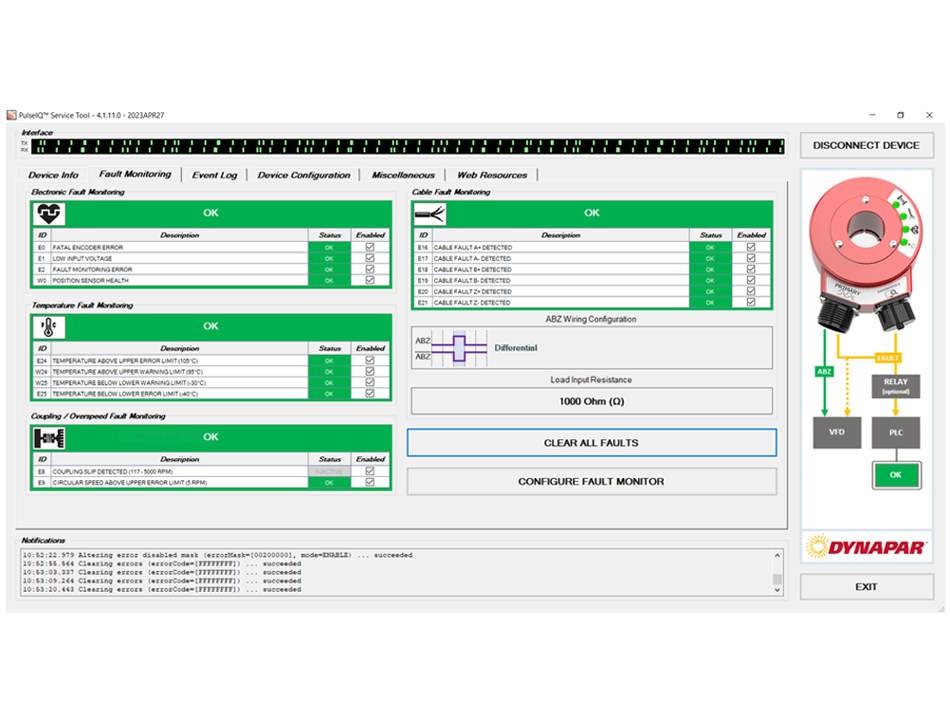

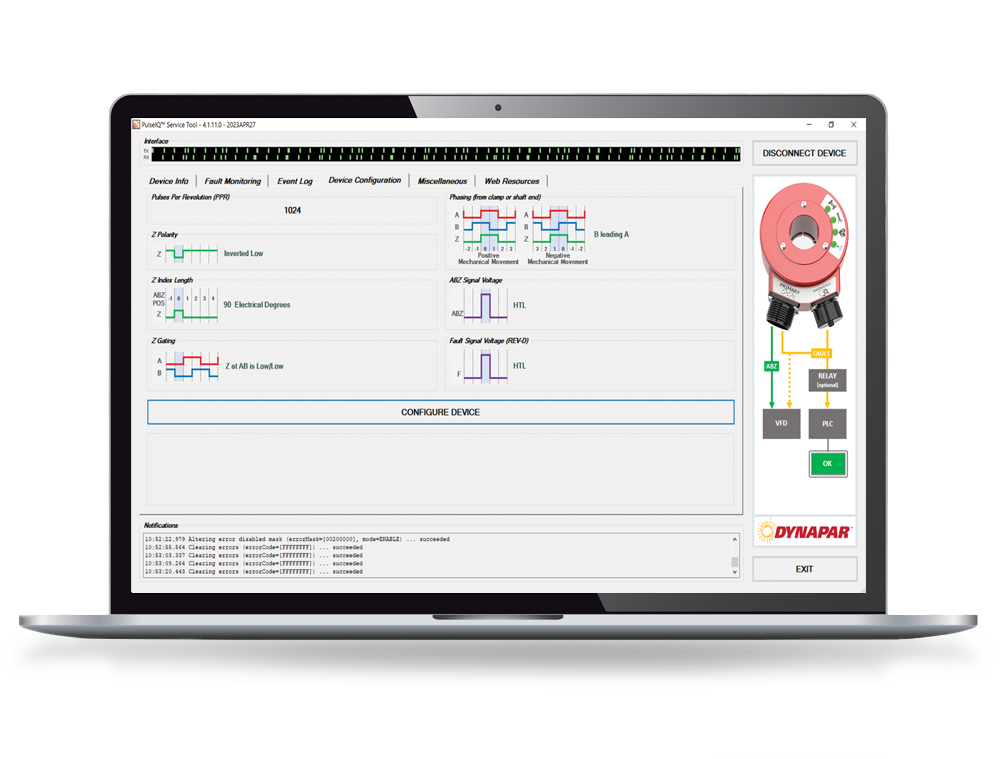

Get Specific Fault Indication

See exactly what is at fault so you can find the root cause with confidence. No more guessing or replacing, only to have the problem occur again.

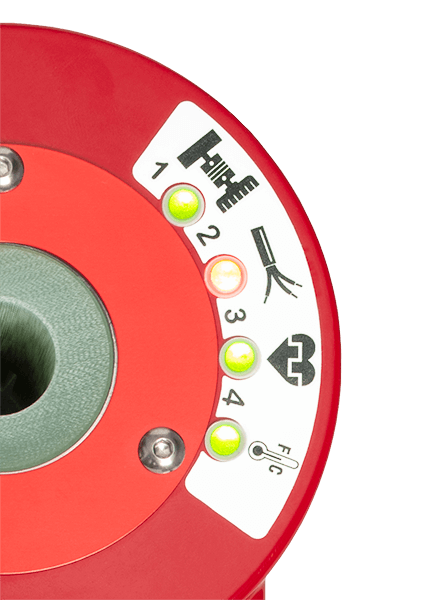

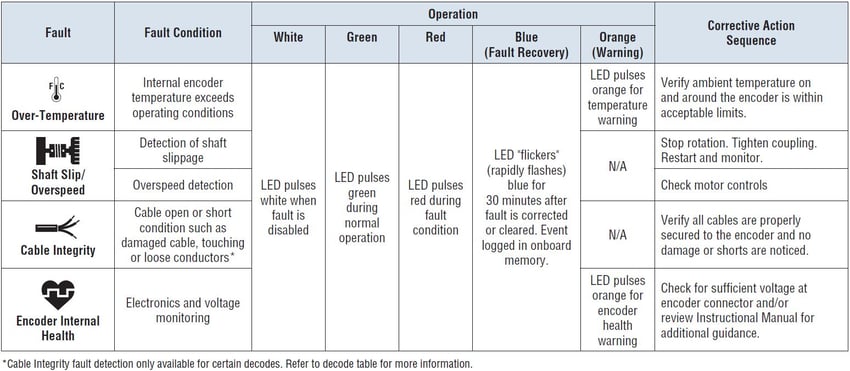

- Insufficient Voltage: Sense supply voltage changes and low voltage conditions that are otherwise difficult to detect.

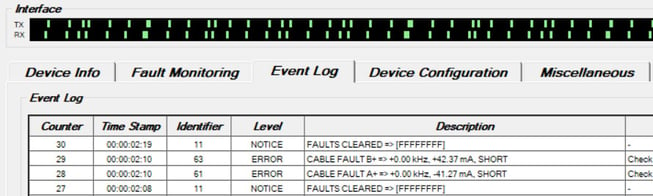

- Cable Integrity: For 7272 differential line driver options, catch encoder cable faults (opens/shorts) such as cable breaks or loose conductors.

- Shaft Slip: Detect clamping collar slip between the shaft and encoder physical connection before coupling failure.

- Overspeed: Detect shaft speed exceeding a predetermined limit.

- Electronic Failure: Continuously monitor electronics which may result in irregular pulse output.

- Over-Temperature: Measure ambient temperature to indicate operating condition changes early.

See product datasheet to learn more about fault conditions, fault LED operation, and potential corrective actions.