- Industrial Encoder

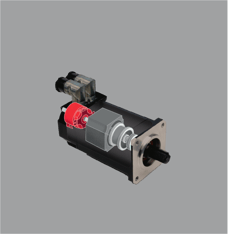

- Motor Encoders

- Resolvers

- Incremental Encoders

- Absolute Rotary Encoders

- Magnetic Encoders

- Optical Shaft Encoders

- Optical Rotary Encoders

- Hollow-Shaft Encoders

- Quadrature Encoders

- Draw Wire Encoders

- Hall-Effect Encoders

- Hazardous Location Encoders

- Functional Safety Encoders

- Encoder Interface Protocols

- BiSS Encoders

- SSI Encoders

- Gray Code Encoders

- What is an Encoder?

- Electric Motor Controllers

- Types of Safety Encoders

How Motor Encoders Work

Motor encoders have two main parts: a disc on the motor shaft and sensors that track the disc's movement. When the motor shaft turns, the disc's patterns touch the sensors, creating electrical pulses that show how much the shaft moves.

Incremental vs. Absolute Encoding

Motor encoders can employ two main encoding schemes: incremental and absolute.

Incremental Encoders: Incremental encoders generate pulses relative to a reference point, typically referred to as the index. Each pulse represents a small angular displacement, allowing the system to track the shaft's movement accurately. These encoders are well-suited for applications where relative position feedback is sufficient.

Absolute Encoders: Absolute encoders give a specific code for each relative shaft position, removing the need for a reference point. This code indicates the shaft's position in one full rotation. This allows for precise positioning without the concern of losing track of its location.

Components of Motor Encoders

Encoders for motors comprise several key components that work in tandem to facilitate accurate motion feedback:

- Shaft: The encoder attaches to the motor shaft. As it rotates, the shaft transmits the motion to the encoder's internal components.

- Disc: The disc, also known as the code wheel, also mounts to the motor shaft. The disc contains patterns or markings that interact with sensors to generate electrical signals.

- Sensors: As the shaft rotates, sensors detect the changes in the disc's pattern and convert these changes into electrical signals.

Motor Encoders Types

Motor encoders come in various types, each tailored to specific applications and performance requirements:

Incremental Encoders:- Incremental encoders generate pulses as the motor shaft rotates, providing relative position information. Each pulse represents a small angular displacement, allowing precise tracking of the shaft's movement. These encoders are cost-effective and widely used in applications where absolute position feedback is not required.

- Absolute encoders give a special code for each motor shaft position, removing the need for a reference point. This code indicates the shaft's position after one full turn. This helps ensure accurate positioning without the need to keep track of its location constantly. Users prefer absolute encoders for applications that require accurate and reliable position feedback.

- Linear encoders measure linear displacement along a straight path, as opposed to rotational movement. They consist of a scale and a read head, with the scale typically featuring evenly spaced markings or gratings. Linear encoders are commonly used in applications such as CNC machining, metrology, and semiconductor manufacturing.

- Rotary encoders measure rotational movement of the motor shaft and are available in both incremental and absolute configurations. They provide shaft position, speed and rotation direction in servo motors, robotics, and industrial automation.

- Magnetic encoders utilize magnetic fields to detect changes in position, offering advantages such as resistance to contamination and high durability. They are suitable for harsh environments and applications requiring robust performance.

- Optical encoders use light to track position changes. They have a light source, a patterned disc, and photodetectors. They offer high resolution and accuracy, making them ideal for precision motion control applications.

- Encoder resolvers are electromechanical devices that convert angular position into an electrical signal. They consist of a rotor and stator with wire windings. Resolvers offer robust performance in harsh environments with high levels of vibration and temperature fluctuations.

Understanding the differences motor encoder types is essential for selecting the most suitable option for specific applications, ensuring optimal performance and reliability.

Comparison of Motor Encoders:

1. Induction Motor Encoders:- Application: commonly used for its simplicity and robustness.

- How it works: Induction motor shaft movement is tracked using magnetic or optical sensors to determine speed and direction.

- Advantages: Robust design, suitable for high-speed and high-torque applications, cost-effective.

- Limitations: Limited precision compared to other types, less suitable for precise positioning applications.

- Application: Ideal for applications requiring precise positioning, such as robotics, CNC machines, and automation systems.

- How it works: Gives detailed feedback on where, how fast, and which way servo motors are moving, allowing for accurate control.

- Advantages: High precision, fast response times, suitable for closed-loop control systems.

- Limitations: Higher cost compared to other types of encoders, may require complex control algorithms.

- Application: Widely used in applications such as printers, robotics, and consumer electronics.

- How it works: give input on how DC motors rotate, usually using optical or magnetic sensors to track movement.

- Advantages: Compact size, low cost, suitable for a wide range of applications.

- Limitations: Limited torque and speed compared to other types of motors, may require additional gearing for higher precision.

- Application: precise control of position and speed, such as 3D printers, CNC machines, and robotic systems.

- How stepper motors work: They give feedback on their position and movement using methods like optical or magnetic sensing.

- Advantages: Excellent precision, easily synchronized with control systems, suitable for open-loop and closed-loop control.

- Limitations: Limited torque at high speeds, may require higher power consumption compared to other types of motors.

Different motor encoders have advantages and disadvantages. They are suitable for specific uses based on needs such as accuracy, speed, power, and price. Knowing the variances between encoder types is crucial for choosing the best one for a specific use, to guarantee top performance.

Applications of Motor Encoders

Motor encoders find widespread use in various industries and applications, including:

- Robotics: In robotic arms and manipulators, motor encoders enable precise control and navigation, ensuring accurate

.jpg?width=230&height=153&name=iStock_000019694926Small%20(1).jpg) positioning and movement.

positioning and movement. - Manufacturing: In CNC machines and automated assembly lines, motor encoders facilitate precise positioning and motion control, resulting in high-quality production.

- Medical devices such as diagnostic equipment and surgical robots use motor encoders for accurate movements and measurements. This helps enhance patient care and improve procedure outcomes. Motor encoders are essential for ensuring precise movements in medical devices. They play a crucial role in improving the accuracy and effectiveness of procedures.

Advantages of Motor Encoders

Motor encoders offer several advantages in industrial automation:

- Precision: provide accurate position feedback, enabling precise control and monitoring of motorized systems.

- Reliability: enhance the reliability and performance of electromechanical systems by ensuring consistent operation.

- Versatility: compatible with various types of motors and can be integrated into diverse applications, offering flexibility and scalability.

Challenges and Considerations

While motor encoders offer numerous benefits, they also pose certain challenges and considerations:

- Environmental Factors: Motor encoders may be susceptible to environmental factors such as temperature fluctuations, mechanical vibrations, and electromagnetic interference, which can affect their performance.

- Selection Criteria: Engineers must carefully consider factors such as resolution, accuracy, operating environment, and communication interface compatibility when selecting motor encoders for specific applications.

Future Trends in Motor Encoder Technology

The future of motor encoder technology holds exciting prospects for innovation and advancement:

- Ongoing advancements in materials science, sensor technology, and signal processing techniques are expected to enhance the performance and reliability of motor encoders.

- Smart features such as predictive maintenance, adaptive control algorithms, and real-time communication will enhance motor encoders in industrial automation. These features will make the motor encoders more efficient and functional.

Conclusion

In conclusion, motor encoders play a crucial role in modern industrial automation, enabling precise motion control and feedback mechanisms in a wide range of applications. By understanding the working principle and functionality of motor encoders, engineers can optimize the performance of electromechanical systems, driving innovation and efficiency in industrial automation.

Motor Encoder FAQ's

1. What is the working principle of a motor encoder?A motor encoder works by translating mechanical motion into electrical signals, typically through methods such as optical or magnetic sensing. These signals provide feedback on parameters such as position, speed, and direction of rotation, enabling precise control and monitoring of motorized systems.

2. How does a motor encoder contribute to precision motion control?Motor encoders play a crucial role in precision motion control by providing accurate feedback on the position, speed, and direction of rotation of motors. This feedback allows control systems to adjust motor parameters in real-time, ensuring precise positioning and movement.

3. What are the different types of motor encoders and their applications?Motor encoders come in various types, including incremental, absolute, linear, rotary, magnetic, optical, and resolver encoders. Each type has unique characteristics and applications, ranging from industrial automation and robotics to CNC machining and medical devices.

4. How do incremental and absolute encoders differ in their working principles?Incremental encoders generate pulses relative to a reference point, providing incremental position feedback. Absolute encoders, on the other hand, provide a unique digital code for every position of the motor shaft, offering absolute position feedback without the need for a reference point.

5. What are the advantages of using motor encoders in industrial applications?Motor encoders offer several advantages in industrial applications, including high precision, reliability, versatility, and compatibility with various types of motors. They enable precise motion control, monitoring, and feedback, enhancing the performance and efficiency of motorized systems.

{{else if (myEq content.heading "Absolute Encoders")}}

{{else if (myEq content.heading "Absolute Encoders")}}

{{/if}}

{{/if}}