Dynapar OnSite™ Condition Monitoring Overview

The Dynapar OnSite™ condition monitoring system is a hardware and software solution that combines flexibility with fast results. The hardware hub captures vibration, temperature and speed (with an encoder present) and transmits it via a Wi-Fi or cellular network. It deploys in minutes: Just attach the sensors, turn on the power and the Dynapar OnSite™ System does the rest. There is no need to download software - the application resides in the cloud. And built-in software tools make it easy to set alarms and analyze data in real time.

Dynapar OnSite™ System

1. Wi-Fi or Cellular Communication

1. Wi-Fi or Cellular Communication

Compatible with existing infrastructure (no proprietary gateway required). Max range: 300m, line of sight.

2. Sensor Node

Installs in minutes with multiple mounting options. Rated at IP65 and 85°C max temp for harsh environments.

3. Sensor Cables

Sensor cable extends up to 30ft for hard to reach locations.

4. Sensors

Each node contains four sensors with tri-axial accelerometers and temperature sensors. Each sensor is rated IP68 and 105°C max for rugged environments.

5. Optional Encoder Input

Connect encoder for speed data allowing full situational awareness of machine condition.

6. Edge Trigger Data Collector

Push button for a quick snapshot of current data.

7. Asset Status Indicator

Visually confirm device status with multifunction LED.

8. QR Code

Scan for quick access to software and commissioning portal.

Dynapar OnSite™ Analytics

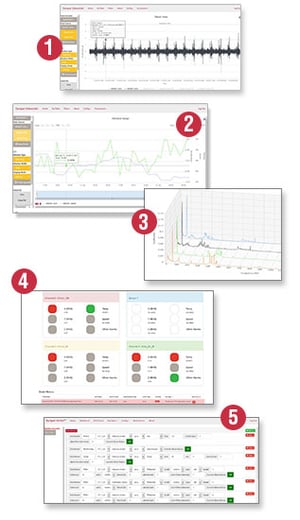

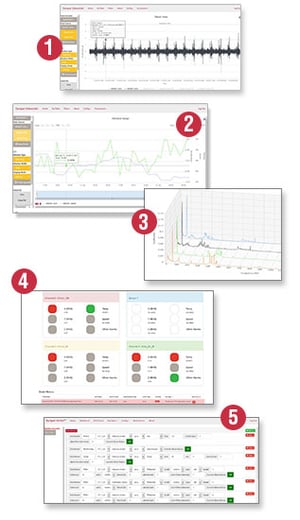

1. Vibration Waveform

1. Vibration Waveform

See an overall trend to quickly spot spikes and issues early.

2. Overall RMS with Speed and Temperature Data

Combine vibration data with speed and temperature to achieve complete situational awareness (encoder input needed for speed data).

3. Advanced Analysis Tools

Advanced analytic tools such as water fall plots and harmonic cursors are built-in for experts to quickly root cause critical issues.

4. Dashboard

Quickly identify troubled assets at a glance and view event history. Dive into the data quickly from the dashboard to determine the issue, not just that an alarm went off.

5. Alarms

Customizable alarms based on user-established thresholds for RMS, FFT, dynamic FFT orders, peak Gs, speed, temperature, missed posts and local data request.

Sensor Specifications

| Operating Temperature Range (Sensor) |

-40°C to 105°C |

| Operating Temperature Range (Hub) |

0°C to 40°C (200 and 500 models)

-20°C to 80°C (DCN and DCS models) |

| Frequency Bandwidth |

0 Hz - 1,000 Hz |

| Measurement Range (programmable) |

Low Mesurement Range Sensor: +/- 8g (Range: 2, 4, 8)

High Mesurement Range Sensor: +/- 40g (Range: 10, 20, 40g) |

| Sensitivity |

15.6 μg/LSB |

| Spectra Line |

Programable (24K max) |

| Sampling Frequency |

4000 Hz |

| Temperature Sensor |

Yes |

| Max Number of Hubs |

255 |

| Frequency Accuracy |

+/- 1 Hz |

| Low-pass Antialiasing Filter |

1.5 kHz |

| Low-pass Digital Filter |

1 kHz |

| High-pass Filter |

DC - 10 Hz Programmable |

|

Condition Monitoring System Overview

Learn more about the Dynapar OnSite™ Condition Monitoring System, view key features and download datasheets. |

|

Online Condition Monitoring Process

Discover how the Dynapar OnSite™ system can change the way you monitor critical assets and eliminate data silos within your organization. |

|

Condition Monitoring Applications

See examples of how plants of all sizes use the Dynapar OnSite™ System to detect problems before they occur, monitor assets and make decisions. |

|

Request More Info

Condition monitoring, reinvented. Discover what the Dynapar OnSite™ System can do for you. Request more information about the OnSite system today. |

1. Wi-Fi or Cellular Communication

1. Wi-Fi or Cellular Communication 1. Vibration Waveform

1. Vibration Waveform