HT55

- Hollow-shaft with tether and collar clamp

- Magnetic sensing, encapsulated electronics

- Bore sizes 1/2" - 2-7/8"

- 256 - 4,096 PPR resolution

- Reverse polarity and short circuit protection

Other Categories

Optical Rotary Encoders

Magnetic Rotary Encoders

Hollow-Shaft Encoders

Hub-Shaft Encoders

Shaft Encoders

Miniature Encoders

Hazardous Area Encoders

Non Contact Encoders

Bearingless Encoders

Ethernet Protocol Encoders

Service & Support Overview

Product Quicklinks

Competitor Parts List

Discontinued Encoder Guide

Literature Library

RMA Request

Technical Support

Product Manuals & Installation Guides

Knowledge Center

Technology

How to Choose Feedback

Application Examples

Case Studies

Encoder Issues and Troubleshooting

White Paper Downloads

Literature Library

Power Point Downloads

Videos

Featured Links

Motor Encoders

Quadrature Encoders

Optical Encoders

Magnetic Encoders

How to Specify a Resolver

Draw Wire Encoders

Hall Effect Encoders

Encoder Accuracy vs Resolution

With over half a century of proven reliability, the next generation of NorthStar encoders continues to provide superior performance with higher resolution, noise resistant electronics, and on-board diagnostics so you can be confident in heavy duty environments.

Be confident in encoder selection with an encoder designed specifically for mills and heavy duty environments.

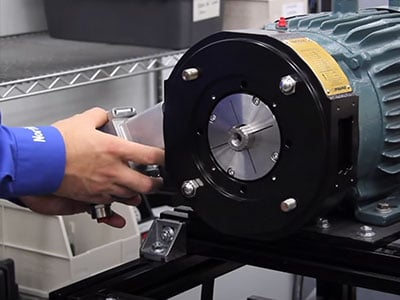

Install quickly and have peace of mind of proper encoder installation thanks to a real-time LED indicator.

Get real-time indication of successful encoder output thanks to the diagnostic LED indicator.

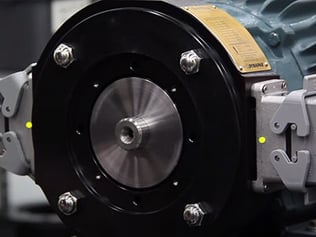

NorthStar hollow shaft encoders are ideal for AC motor applications with no NEMA C-face mounting provisions or mounting through fan shrouds in heavy-duty markets such as pulp, paper, steel mills, and cranes. In addition to heavy duty optical encoders, NorthStar magnetic hollow shaft encoders offer fully encapsulated electrics for improved environmental protection. Magnetic encoders offer superior protection in applications with dust, moisture, and contaminants common in heavy duty environments. Other feature include:

NorthStar offers a variety of mill-duty, bearingless encoders with magnetic sensing for maximum reliability. Fully encapsulated electronics and cast iron housing options enable these NEMA C-Face solutions to withstand the harshness of heavy-duty mill applications. Bearingless encoders also offer field replaceable sensor wheels and replaceable sensor modules for RIM Tach models for improved longevity. Other features include:

NorthStar foot mount encoder solutions are rugged and reliable thanks to dual large-sealed bearings for greater bearing load capacity. Foot mount solutions mount via flexible shaft couplings, which offer improved resistance to misalignment compared to hollow shaft encoders. The R56 foot mount solution is also offered with resolver sensing technology for improve temperature performance. Other features include:

Rely on our team to provide timely solutions to your inquiries regarding product selection and improving system reliability. Fill out the form and our team will contact you and provide assistance and technical expertise.

Our experts can help:

© Copyright Dynapar 2026 All Rights Reserved