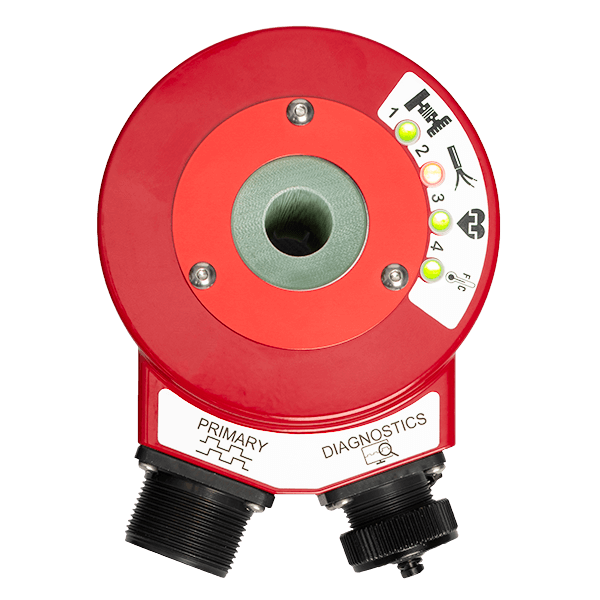

Troubleshoot Confidently with Visuals

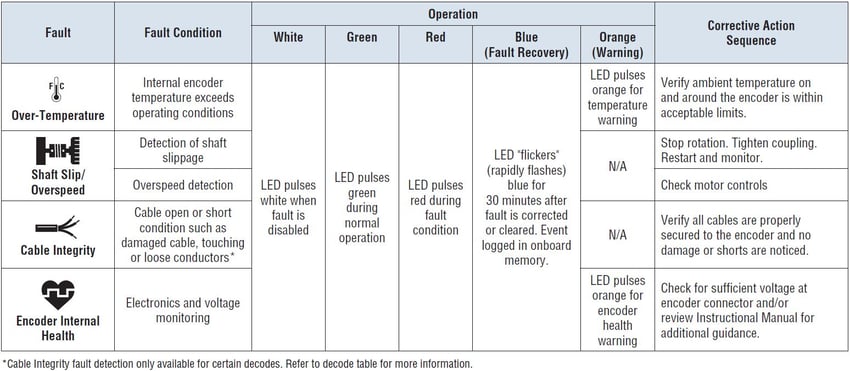

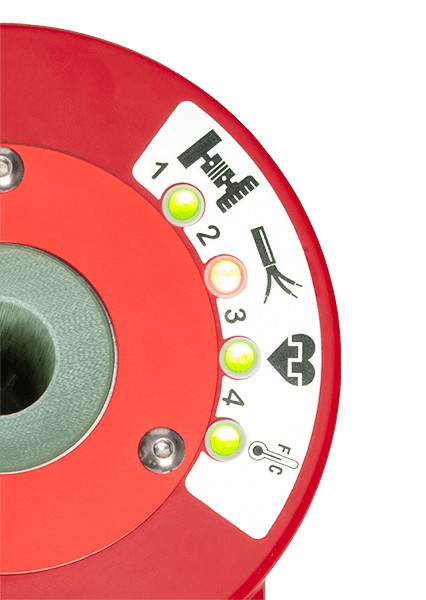

No more trial and error. Quickly review fault conditions and diagnostic the problem without wasting time with visual indication of fault condition is provided by 4 fault status LEDs.

Digital fault output is also provided via a dedicated output signal, which can be connected to a PLC.

See an example of how to connect fault output to a PLC here.