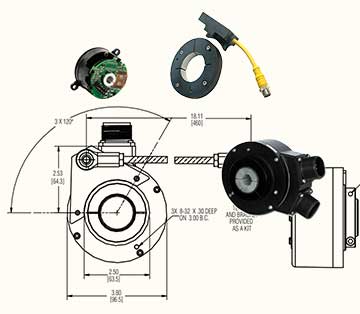

HSD35 Heavy Duty Optical Encoder

Heavy Duty Optical Encoder with Extremely Rugged Design and Field Serviceable Latching Connectors

- Rugged Design Resists up to 400g Shock

- Stainless Steel Clamp and Hub-Shaft for Mill Duty

- Compact Design with Field Serviceable Connector for Solder-Less Connections

- Accommodates Shaft Sizes up to 1.25” (Electrically Isolated up to 1.125”)

- Dual Isolated Output Option for Redundancy

- 400G Shock and 20G Vibration Independently Validated

- Technical Data

- Accessories

Description

The HSD35 encoder is similar to our HS35R but with EPIC/Latching industrial connectors, stainless steel shaft/clamp and Viton seals making this and ideal encoder for Mill applications.General

Mechanical

Electrical

- Open Collector

- Open Collector With Pull-Up

- Push-Pull

- DLD 7272

- DLD 4469

Environmental

Technical Information

Drawing

Marketing Materials

Certifications

Industries

- Factory Automation

- Oil & Gas

- Pulp & Paper

- Steel Mills

- Vector Motor

Applications

- Motor and Drive Speed Feedback

- Extruders

- Pickling Equipment

- Processing Equipment

- Paper Machines

- Line shaft / belt driven equipment

- Cranes

- Test Stands