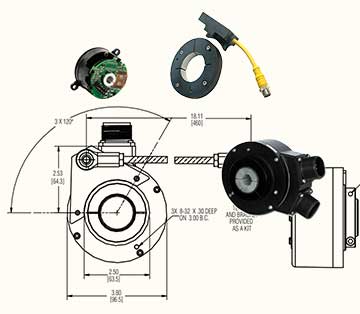

Description

The NorthStar™ brand RIM Tach™ 1250 digital tachometer provides position and velocity feedback from both AC & DC electric motors, providing precise, reliable speed signals for many monitoring and control applications

Feedback Type

Incremental

Technology

Magnetic

Mounting Configuration

Bearingless 12.5" C-Face mount

Encoder Size (Flange)

12.5" C-Face

Hollow Bore Size

5/8"-2 7/8"

Housing Material

Cast Iron/Stainless Steel

Max. Operating Speed

7,000 RPM

Resolution

60-1200 PPR

Supply Voltage

5-15VDC, 15-26VDC

Interfaces

DLD 4428

Approvals / Certifications

CE, ROHS

Operating Temperature Range

-40ºC to 80ºC

Storage Temperature

-40ºC to +125ºC

Enviroment

Non-Hazardous