Description

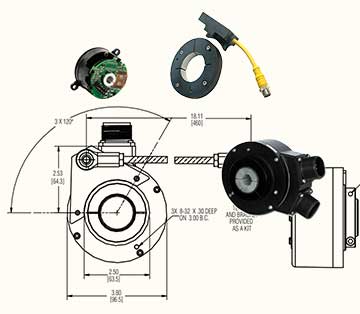

The Series F18 encoder provides high performance, cost effective feedback for stepper and servo motor controls. The F18 offers compact package dimensions, extremely high PPR capabilities and a pluggable pin header.

Feedback Type

Incremental

Technology

Optical

Mounting Configuration

Four standard configurations are available for tethers. A choice of U.S. and Metric screws are included.

Encoder Size (Flange)

<2.0"

Hollow Bore Size

1/4" to 1/2" or 6mm-12mm Bore

Housing Material

Plastic

Max. Operating Speed

12,000 RPM

Resolution

500-5000 PPR

Supply Voltage

5 VDC

Protection Class (IP)

IP40

Approvals / Certifications

CE, ROHS

Operating Temperature Range

0ºC to +120ºC

Storage Temperature

-40ºC to +120ºC

Enviroment

Non-Hazardous